After a year of growing in nature’s bounty, the olives are ready to be harvested…

All throughout the sorting and oil-extracting area, a soft fragrance floats on the air…

Making great olive oil begins in the olive groves, where we spend each year ensuring the best possible harvest in the autumn. On this page, we will explain how our olives become some of the finest olive oil on the market today.

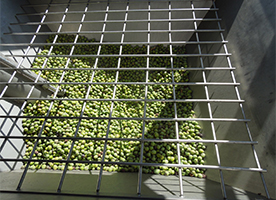

After harvest, our olives are first brought into our sorting area, where twigs, leaves, and other impurities are carefully picked out; then the olives make their way to the processing area. Time is of the essence, and the less that passes between picking and processing, the better. As a rule, we try to extract oil olives on the day they are harvested, if not the morning after.

Once we start the extractor machine, it cannot be stopped, so we have to coordinate with the pickers out in the groves to keep everything running smoothly. Farm workers make sure that once we get going, we have a steady supply of olives to run efficiently. This cooperation between the harvesters and the workers in the extraction area is how we ensure that our olives are turned into oil at their freshest, best point.

There are three main methods of olive extraction: pressing, centrifugation, and percolation. At Takao Olive Farm, we use centrifugation to produce our olive oil.

Harvest

Like other cultivars, olives have different ripening periods, so it is essential to harvest them at the peak of their season. Once we decide when to start the harvest, we carefully check the olives as we go to determine when we must finish. We also have to adjust our schedule due to weather factors like rain.

All our olives are harvested by hand. We use containers that let the olives breathe after harvest, so they don’t get too hot or damaged, and also avoid filling containers too full and crowding them. We take pains to ensure the olives do not come into contact with the ground, as soil can affect their flavor.

Using ladders to harvest olives

Harvesting

Freshly harvested olives

Checking temperature

Sorting & Rinsing

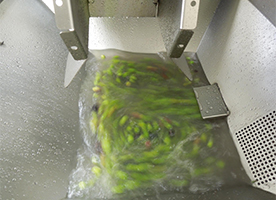

We carefully pick over the harvested olives to remove impurities like twigs and leaves. If any leaves should get sent on to the extractor, they will turn the olive oil bitter, with a strong leafy fragrance, unfit for consumption. After carefully rinsing the olives, they go straight to the extractor.

Olives before sorting

Olives being picked over

Sorting

Olives ready for the crusher

Crushing

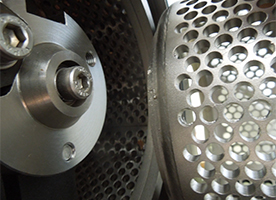

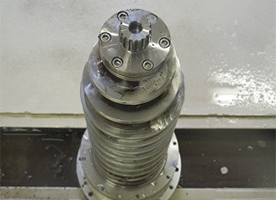

At this step, the olives are crushed to create a paste. This is accomplished using a knife crusher, which turns to cut up the olives and extrude them through small grid holes in the crusher’s drum. There are two sizes of grids, 4mm and 6mm, and depending on olive type, moisture content, ripeness, etc. workers decide which grid is best. While it may seem like a small difference, choosing the wrong size grid can cause overheating or the final paste to come out runny.

Rinsing before crushing

Olives going into the crusher

Sending olives to be crushed

Grid & Knife

Malaxing

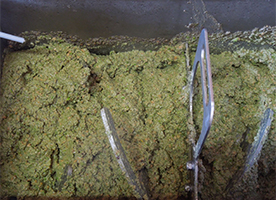

Once the paste is ready, it goes into a malaxing (mixing) tank. Once inside, it gets mixed with a propeller-like implement that slowly turns to bring oil droplets together. The temperature of the paste during malaxing must not exceed 27 degrees centigrade, nor go lower than 18; this means timing must be adjusted for the day’s conditions, and can last from 20 to 45 minutes. While mixing for a longer time can yield more olive oil, the final taste can take on burnt or caramel overtones that make it unsuitable for consumption.

Switches on the malaxer

Low-moisture paste

High-moisture paste

Oil is beginning to separate

Separation

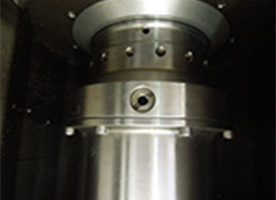

After the paste has been sufficiently mixed, it is sent on to the centrifuge. This machine will separate the oil from the olive fruit and juice (two phase decanter.) The olive paste is spun quickly so that the components come apart by weight. The difficulty with the centrifuge lies in its two nozzles, from which the oil comes out. Push them in too far and less oil will be extracted; on the other hand, if they’re not pushed in far enough, the oil will be clouded by fruit particles. It takes a good understanding of the paste’s condition and how the centrifuge works to get the nozzles in at just the right place. I always make sure to picture in my mind what is going on inside the machine, which I use as a hint when manually adjusting the machine by 0.25mm.

Operation labo

Centrifuge

Centrifuge nozzle

Inside the centrifuge

Filtration & Storage

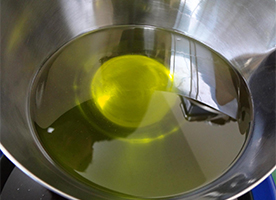

Freshly extracted olive oil is still opaque, with some sediment remaining. While unfiltered olive oil is still delicious to use, the sediment will eventually start to have a negative effect on flavor. This is why we continue on to the next important step, which is the filtration process. We take extreme care to filter our oil until it becomes a brilliant light green.

Once we have filtered the oil, we separate them out by type, then store them in temperature controlled areas to make sure they never get too hot in early autumn, or too cold in the autumn chill (not warmer than 17℃ or cooler than 13℃).

Olive oil coming out of the centrifuge

Check oil immediately after pressingextractingr

Oil after filtration

Stainless storage tanks for olive oil

Packaging

Once harvesting and processing the olives is finished, it is time to get the oil ready for consumers. We open each stainless storage tank one by one and conduct taste tests for quality.

While we do all the harvesting and processing on site at Takao Olive Farm, we send out finished oil to Takahashi Shoten, our retail partner. After bringing the oil and larger stainless packing tanks to their packaging facility, we check to make sure that nothing is amiss after transport. We then transfer the oil (by type) into larger tanks.

Even within the same olive type, harvest time or weather conditions can create very subtle changes in oil flavor. This is why all the storage tanks we fill after the filtration process get mixed together in larger tanks at Takahashi Shoten; our olive oils have a uniform flavor. Once this is done, it is ready to be packaged.

Though the biggest enemy of olive oil is light (with heat and air close seconds), we use transparent bottles so that customers can enjoy our oil’s vivid green color. If customers are not planning to use the oil up in a short period of time, it’s best to wrap the bottle in aluminum foil or protect it some other way. We do suggest that oils be used quickly once opened, to ensure maximum flavor and aroma.

Oil before packing

Packing into glass bottles (1)

Packing into glass bottles (2)

Putting Label